In the 1980s, most car stereo shops had charts in the install bays that showed what size power wire should be used with different amplifiers. Some charts were based on current and cable length, while others suggested amplifier power ratings and lengths. In all cases, an essential piece of information was missing. Today, we’ll sort that out. Let’s consider why we need large power wires, what factors affect the current draw, and how to select the wiring that’s the right size for your car’s audio amplifier.

Low-Voltage Electrical Systems

Most cars, trucks, boats and motorcycles operate on a 12-volt electrical system. The battery should rest between 12.2 and 12.6 volts when the vehicle isn’t running. Depending on the application, we might see 13.4 to 14.6 volts when the alternator charges the battery. These voltages might be slightly higher if your vehicle uses an AGM battery.

Power is the product of voltage times current. So, if a load like an amplifier or light needs 100 watts from the 12-volt electrical system, it will draw 8.3 amps of current. If we want 1,200 watts, we need 100 amps of current. This is Ohm’s law at its most basic.

Now, if we had the 120 volts we find in our homes and offices, the current draw for 100 watts would only be 830 milliamps. A load of 1,200 watts would only draw 10 amps. The amplifier might have a 240-volt supply if this was a concert or sizeable public-address application. If so, it would only draw 415 milliamps of current at 100 watts and 5 amps at 1,200 watts.

Here’s the problem with large amounts of current flowing in electrical conductors. The formula to calculate power is Current squared times Resistance. If we have a conductor with 10 amps of current flowing and 0.005 ohm of resistance, a voltage drop of 50 millivolts will be present across the wire, and 0.5 watt of energy will be wasted as heat. If that current draw increased to 20 amps, the heat wasted in the wire jumps to 2 watts. At 50 amps, 12.5 watts of energy is wasted in the wire; at 100 amps, there is 50 watts. This is the equivalent resistance to 12 feet of all-copper, full-AWG spec 6 AWG wire. Think about how hot a 50-watt incandescent lightbulb gets after being on for only a few minutes.

Cable resistance is why electric utility companies transmit power across the country at levels like 345,000 volts. You can transmit massive amounts of power this way without incurring significant losses from cable resistance.

Amplifier Efficiency Is Crucial

The second item to remember is that no electrical or electronic device is 100% efficient. This means you put more power into the device than you get out. Car audio amplifiers vary dramatically in their efficiency. We’ve seen subwoofer amplifiers offering more than 92% efficiency and others less than 58%. The amplifier’s efficiency plays a massive role in determining how much power it will consume.

Let’s say, for example, the above amplifiers are both rated to produce 1,000 watts of power. The 92% efficient amp would draw about 87 amps of current from a 12.5-volt electrical system. The inefficient amp would draw a comparatively mind-boggling 138 amps to produce the same power. Statements about power cable requirements based on amplifier power ratings need to be scrutinized.

Music and Test Tones

It stands to reason that we want to size the wire in our car audio system for a worst-case scenario. We don’t want to waste energy when we max out the power production capabilities of the amplifiers. However, average power consumption is much lower. We’ve analyzed a good amount of modern music, and the average power level is around 7.5 dB below the peaks. This means that if we average the power requirements of our amplifiers over the length of a song, they produce less than 20% of their maximum power when set so the peaks reach clipping.

Turn the volume down one notch, and the current requirements will likely drop by half. It stands to reason that we could, theoretically, undersize the power wire significantly and not run into much trouble. We’ve seen dozens, if not hundreds, of large amplifiers installed with woefully undersized power wiring. Is this a “best practice”? Most assuredly not. However, it happens frequently, and most of these installations don’t run into issues. Is there a downside? Yes, the amplifier will likely never make its maximum power rating, so you’re limiting the performance of your audio system.

What Determines Acceptable Wire Size?

The answer to the question, “What wire size is right for my amplifier?” requires that we pick an acceptable amount of waste or loss. Specifically, how much voltage drop is acceptable across the length of the power wire? The ANSI/CTA-2031 standard for car audio power wiring suggests we select power wire based on a maximum voltage drop of 0.25 volt. Given that the resistance of all-copper, full AWG-spec wire has precise nominal and maximum resistance requirements, we can create a table that provides the maximum allowable current in varying lengths of commonly available wires.

The chart above outlines the maximum allowable current for a given wire size (on the vertical scale) and length (on the horizontal scale). For example, if we have 16 feet of 4 AWG wire, we want to keep the maximum current draw to 58.3 amps. Putting that number back into our amplifier efficiency means we can run an efficient 670-watt amplifier or a 423-watt low-efficiency amplifier without exceeding 0.25 volt of drop across the wire.

One common mistake is to think of the values in this chart as a target. They are a worst-case scenario. For example, if you need to provide 60 amps of current to an amplifier, then 16 feet of 4 AWG wire seems about right. What about the ground wire? It only needs to be 2 feet. Would we want 2 feet of 14 AWG wire? Most definitely not. The goal is to have as little resistance as possible in the power wire to and from the amplifier. Use the same wire for all power connections.

Wasted Energy in Wiring

Now, this isn’t the end of the discussion. We always want to know what happens at those extreme limits, right? The chart says we can draw 2,412 amps of current through 2 feet of 4/0 (0000) wire. That sounds like fun! Or does it?

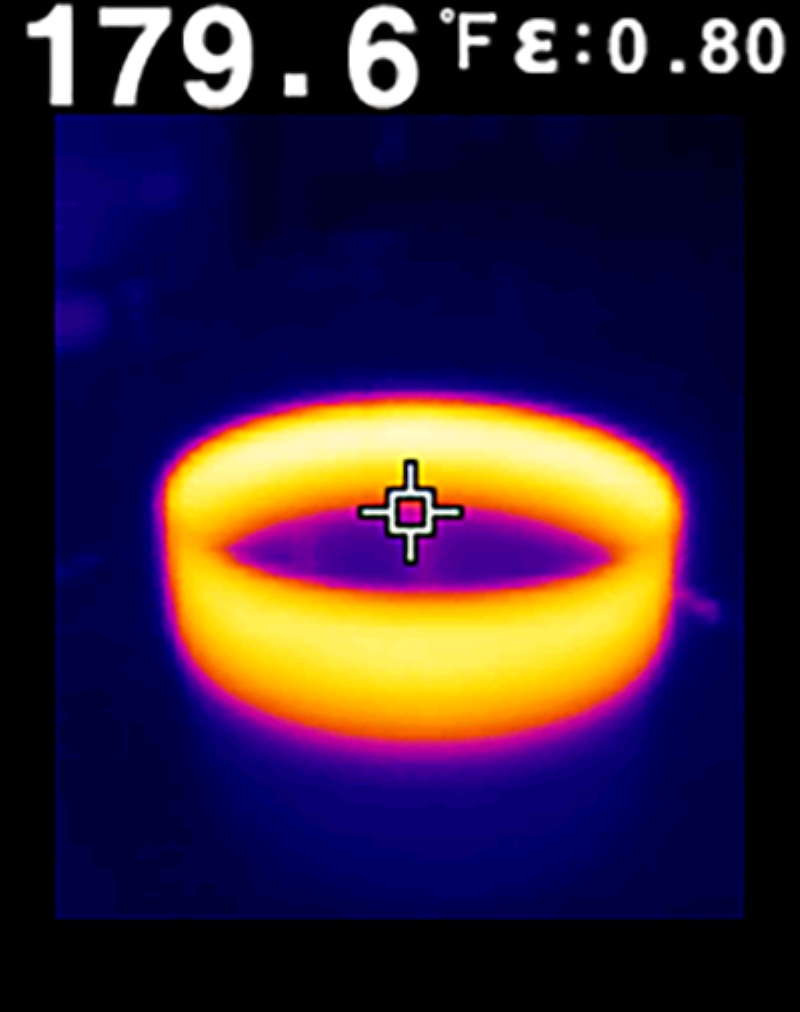

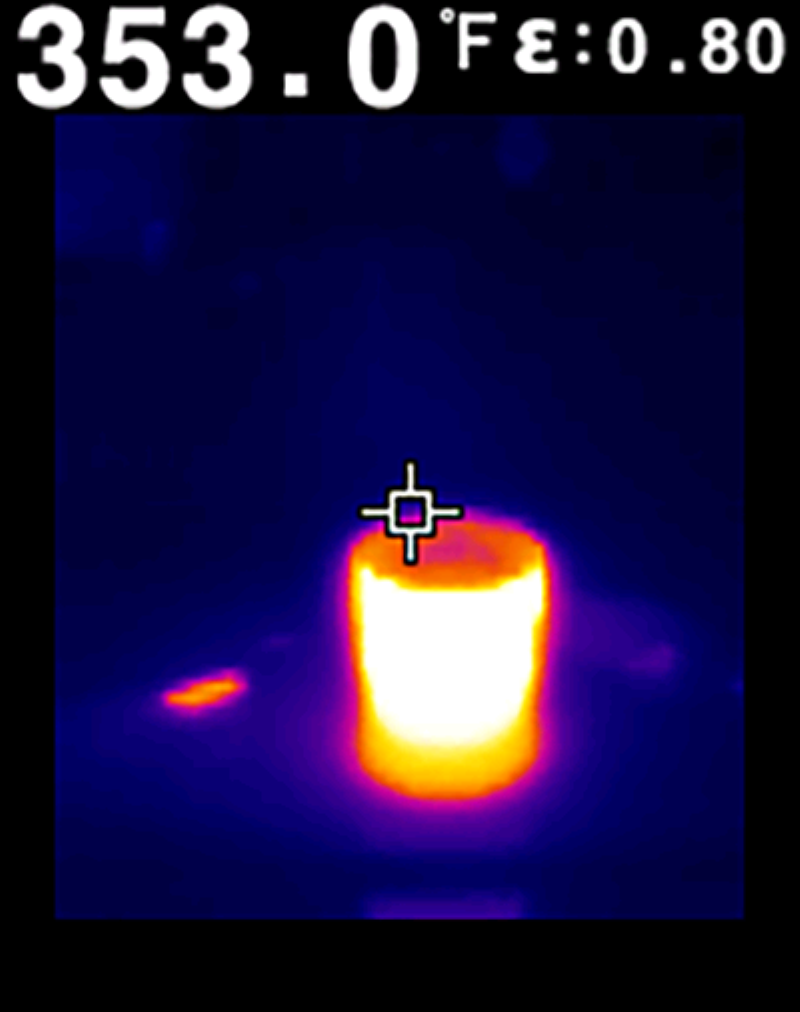

We need to calculate how much power is wasted in the wire. Two thousand four hundred amps is a lot of current. Here’s a second chart that outlines how much power is wasted (as heat) per foot of the conductor.

The chart above shows how much heat is generated if we draw the maximum possible current to provide a 0.25-volt drop through conductors of different lengths. So, our 4/0 cable with 2,412 amps flowing through it will produce 301.6 watts of heat per foot. I don’t need to tell you that the jacket on the wire will melt off quickly. Our calculations show that a bare 4/0 wire heats at a rate of 121 degrees Celsius per minute when producing 301.6 watts. Most wiring is rated for only 105 degrees C. I’m sure you see the problem. Even if we’re way off on our calculations, managing or, more accurately, preventing heat in conductors is crucial in making sure that the wiring in a car’s audio system functions reliably.

Big Wire Is Expensive

While the math checks out, using 16 feet of 2/0 cable for a good ~1,200-watt amp is expensive, right? What if we allow for 0.5 volt of drop across our power wire? Yes, the maximum power out of the amplifier will decrease, and the wire will get hotter. However, it won’t hit our wallets quite as hard. Is the trade-off worth it?

Here are the same charts again with 0.5 volt allowed as the drop.

With the higher allowable voltage drop, the maximum current for a given wire size and length increases significantly. Our 4 AWG wire is supposedly acceptable for 116.5 amps of current or a really efficient 1,000-watt amplifier. The 2/0 cable can supposedly handle 186 amps of current. It would be a good choice for a similarly powerful low-efficiency amplifier.

Wire Size Reality Check

While charts and spreadsheet calculations are interesting, the reality is that there are practical thermal limits that can’t be exceeded. How exciting would 4,800 amps of current through a 4/0 conductor be in creating a fireworks show? The answer is fascinating.

The maximum current a conductor can handle continuously has a lot to do with the environment in which it is used. Under the hood of your car or truck, where it’s likely very hot, the hot wire will heat up even more as current flows through it. This has the effect of increasing resistance. More resistance for a given amount of current means even more voltage drop and more heat being generated.

To put constant current demands into perspective, electric arc furnaces like those used to create steel often use 40,000 to 60,000 amps of current. The conductors that pass this current are sized in the thousands of square millimeters. A 0 AWG cable is 53.5 square millimeters. The furnace cables are usually encased in liquid cooling systems to maintain the conductor temperature. Yes, liquid-cooled conductors.

What Wire Size Does My Car Audio Amplifier Need?

What wire size you need depends on how your audio system will be used, the music you play, and the efficiency of the amplifiers. Rock or heavy metal music is more likely to have dynamic bass information, while rap or EDM is much more likely to have lengthy low-frequency notes. The energy the subwoofer amp requires will differ significantly for these two applications.

If you want to get the most power from your amplifiers, targeting a maximum voltage drop across the longest length of wire of 0.25 volt is a good reference point. If you aren’t as concerned about power as the installation cost, then the 0.5-volt drop chart is an acceptable concession.

Remember that the charts above are based on full AWG-sized, all-copper conductors. If your installer intends to use tinned copper, you might need a one size larger wire. If the wire is undersized or constructed of copper-clad aluminum, it’s anyone’s guess how much current it can handle. Work with a specialty mobile electronics retailer to choose high-performance amplifiers and appropriately sized power wires to ensure that your car stereo sounds great and performs reliably.

This article is written and produced by the team at www.BestCarAudio.com. Reproduction or use of any kind is prohibited without the express written permission of 1sixty8 media.